Generators

When cleaning generators it is important to utilize a solution that will not damage the delicate windings. A cleaning solution that can be effective yet gentle is required. Corn cob blasting, wiping, and brushing are just a few methods that have been used for cleaning generators. However, corn cob blasting is a messy process that hand cleaning is labour-intensive and time consuming. By utilizing the dry ice splitter nozzle this cleaning can be achieved without damage to the windings. The Splitter breaks the ice pellets up into a tiny granulate; making it the perfect solution for the delicate windings.

Heat Exchangers

The removal of soot layers on heat exchanging pipes inside the boil sections at power plants is an important cleaning task that must be carried out for optimal use of heating power. The isolating properties of the soot layer have a negative effect on the heating and cooling of the pipes. Additionally, having a clear view of welds during inspections is important in order to maintain a secure environment. Traditionally, sand blasting has been used as a method of cleaning; however, this has resulted in two major inconveniences. First, it is time consuming and costly to recollect and dispose of the waste after cleaning. Second, sand blasting can create abrasion on the heat exchanging pipes that can lead to a need for repair and eventual replacement. Heat exchanging pipes can be cleaned without damage because dry ice blasting is a non-abrasive cleaning method. Additionally, there is no secondary waste to clean up.

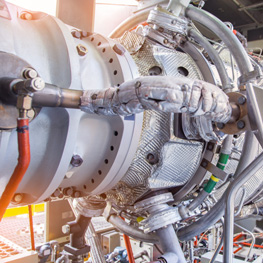

Gas Turbines

Gas turbines can be scheduled for a maintenance overhaul that last up to 20 or 30 days. During this time the removal of contamination is a major part of the schedule. During this process the compressor blades, compressor casings, seals, bolts and dowels, gears, and auxiliary components need to be cleaned. Contamination such as fowling, soot, hardened carbon, oil, and rust need to be removed.

Implementing dry ice cleaning can greatly reduce downtime and eliminate wear and tear of parts during cleaning. Compared to using solvents, there are no leftover resides in inaccessible locations of the machinery.