The use of a dry ice blasting machine is a dry, non-toxic, non-conductive and non-abrasive way to clean production equipment. It has already found valuable use in a wide range of industries such as:

- Aerospace and defence

- Automotive

- Electronics

- Food and packaging

- Foundry

- Medical and pharmaceutical

- Printing

- Plastic and rubber

- Power generation

Dry ice blasting machine applications

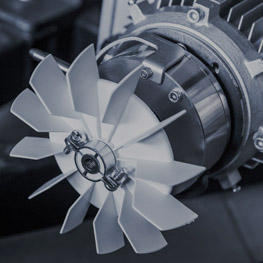

For example, there’s a need for an effective and yet gentle cleaning method when dealing with generators. The windings are delicate and other cleaning methods might result to damage. Although manual cleaning is still possible, it’s labour-intensive and time-consuming.

It’s a similar case when cleaning food processing equipment. Crumbs, waxes, proteins and residues can build up in the food processing facilities. The build-up of dirt and residues might then affect food quality. As a result, it’s important to apply a proper cleaning method while also ensuring that there will be no chemicals and solvents left behind after the cleaning.

Dry ice cleaning is an effective and economic way in maintaining various equipment. No chemicals and residues will remain because dry ice directly turns into gas. The method’s effectiveness in cleaning comes from the ability of the dry ice to loosen the contaminant and the high velocity at which the dry ice pellets impact the surface.

Dry ice cleaning has also become a great choice because corrosion is not an issue anymore. Corrosion is costly and inevitable but dry ice cleaning helps reduce that because the cleaning method doesn’t require the use of moisture. Electrical failure is not an issue as well because the method doesn’t wet the equipment.

This cleaning method has also helped many companies from different industries to save hours from downtime and scheduled maintenance. There’s no need to wait several hours for the equipment to dry. The production schedule will resume to normal sooner.

Another advantage is that the method is an environment-friendly way of cleaning various production equipment. There’s no need to use hazardous chemicals and solvents to remove residues. This is a great way to perform cleaning and maintenance on equipment while minimising environmental impact.